FIBC Bulk Bag Construction Types Explained: A Complete Guide

Key Takeaways:

- Different FIBC construction types—U-panel, circular, four-panel, baffled, and conical—serve specific purposes based on the material being transported, discharge needs, and space efficiency.

- Baffled and four-panel bags offer superior shape retention and stacking performance, while conical bags are ideal for sticky materials that require easy discharge.

- Langgeng Jaya Group provides tailored FIBC solutions, helping businesses select the most cost-effective and operationally efficient bulk bags for their specific industry requirements.

Flexible Intermediate Bulk Containers (FIBCs), commonly referred to as bulk bags, are widely used for the storage and transportation of dry, flowable materials. With their customizable designs and construction types, these bags cater to various industrial needs.

Understanding the differences between construction types is essential for selecting the right FIBC for your business. This guide explains the most common FIBC construction types and their applications.

1. U-Panel Construction

U-panel bags are made using three fabric pieces: a single piece forming the bottom and two opposing sides (resembling a "U" shape), and two additional panels completing the structure.

Key Features:

- Durable and cost-effective.

- Maintains a square shape when filled, especially with the addition of internal baffles.

- Suitable for a wide range of applications.

Applications:

- Commonly used in industries such as agriculture, chemicals, and construction for materials like grains, powders, and sand.

2. Circular (Tubular) Construction

Circular FIBCs are crafted from a single piece of woven polypropylene fabric in a continuous tubular shape, eliminating vertical seams along the main body.

Key Features:

- Seamless design minimizes the risk of product leakage.

- Offers enhanced strength for fine or lightweight materials.

- May bulge when filled without internal baffles.

Applications:

- Ideal for fine powders and granules, such as flour, cement, or sugar.

Learn More : Circular vs. U-Panel FIBC / Bulk Bags - Which Is Better?

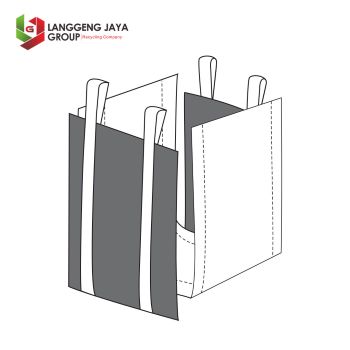

3. Four-Panel Construction

As the name suggests, four-panel bags consist of four individual fabric pieces sewn together to create a square structure, with an additional piece forming the base.

Key Features:

- Provides excellent stability and retains a square shape when filled.

- Facilitates efficient stacking and storage.

Applications:

- Preferred for transporting heavier materials, including minerals, fertilizers, and plastic resins.

4. Baffled (Q-Bag) Construction

Baffled FIBCs, or Q-bags, are designed with internal panels (baffles) sewn into each corner of the bag. These panels enhance the bag’s cubic shape by preventing bulging.

Key Features:

- Optimizes space utilization during storage and transport.

- Maintains stability and reduces the risk of tipping.

Applications:

- Commonly used in industries where efficient space management is critical, such as logistics and warehousing.

Also Read : A Complete Guide to Choosing the Right FIBC / Bulk Bags for Your Business

5. Conical Construction

Conical FIBCs feature a tapered bottom, designed to facilitate the discharge of certain materials.

Key Features:

- Allows for smooth and complete emptying of materials.

- Ideal for products prone to sticking, such as powders or sticky substances.

Applications:

- Popular in the food, pharmaceutical, and chemical industries.

Selecting the Right FIBC Construction Type

When choosing the appropriate FIBC for your business, consider the following factors:

- Material Type: Fine powders benefit from circular designs, while bulkier or heavier materials may require four-panel or U-panel bags.

- Space Efficiency: For optimal storage and transport, baffled bags are ideal.

- Ease of Handling: If quick discharge is essential, conical bags may be the best choice.

- Cost and Durability: Assess the trade-off between budget and the durability of the bag’s construction.

Also Read : Polypropylene vs. Polyethylene FIBCs - Which is Better?

Conclusion

Each FIBC construction type offers unique advantages tailored to specific materials and operational needs. By understanding these differences, you can ensure your bulk bags provide the safety, efficiency, and cost-effectiveness your company requires.

For further guidance or custom bulk bag solutions, reach out to trusted manufacturers like Langgeng Jaya Group, who offer a wide range of high-quality FIBCs for global shipping needs.