7 Essential Considerations Before Buying Industrial Strapping

Key Takeaways:

- Choose strapping based on load and environment: Use PP for light loads, PET for heavy, UV-exposed loads, and steel for extreme weight or rigid items.

- Strapping strength depends on both material and sealing method: Evaluate tensile strength, elongation, and joint efficiency to ensure secure transit.

- Factor in total cost and compliance: Beyond price, consider equipment needs, long-term savings, and ASTM/ISO certifications for reliable, regulation-ready packaging.

Industrial strapping plays a crucial role in securing goods for storage and transportation. However, selecting the right strapping material can significantly impact your packaging efficiency, product safety, and overall costs.

If you work in a company that relies on strapping for bundling, palletizing, or securing shipments, here are seven critical factors you need to consider before making a purchase.

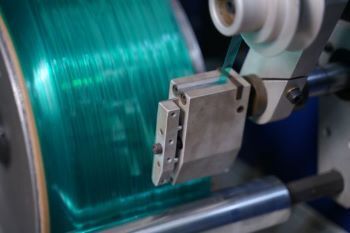

1. Choosing the Right Strapping Material

The type of strapping you choose affects load security, durability, and cost-efficiency. Here’s a breakdown of common materials:

- Polyester (PET): Best for securing heavy loads due to its high tensile strength and UV resistance. PET Strapping is a great alternative to steel for many applications.

- Polypropylene (PP): Lightweight, affordable, and suitable for light to medium loads. However, it has lower tensile strength and may not withstand rough handling.

- Steel Strapping: The strongest option for securing rigid and extremely heavy loads. However, it can rust and is more expensive than plastic alternatives.

Tip: If you need a balance between strength and cost, PET strapping is an excellent choice.

2. Understanding Tensile Strength and Load Capacity

Tensile strength determines how much force strapping can withstand before breaking. Choosing the right strength ensures safe transportation and prevents product damage.

It’s typically measured in pounds per square inch (PSI) or Newtons per square millimeter (N/mm²). Here's a quick guide:

- PP Strapping: 300-600 PSI, typically supporting loads up to 220-600 lbs.

- PET Strapping: 1,000-2,000 PSI, capable of holding loads between 600-2,000 lbs.

- Steel Strapping: Over 5,000 PSI, supporting loads exceeding 5,000 lbs.

For heavy-duty applications, PET or steel strapping is recommended, while PP is sufficient for lighter packaging needs. If your products require extra durability and higher load-bearing capacity, PET is the better plastic strapping option.

3. Considering Elongation and Shock Absorption

If your shipments involve frequent movement or vibrations, you need strapping that can absorb shocks and maintain tension:

- High Elongation (PET): Absorbs shocks during transit, making it ideal for dynamic loads.

- Low Elongation (Steel, PP): Provides a firm hold, best for static loads.

Choosing the right elongation level prevents load shifts and potential damage.

4. Assessing Environmental Resistance

Strapping needs to withstand environmental conditions such as moisture, UV exposure, and temperature fluctuations:

- UV Resistance: PET strapping is highly resistant, making it suitable for outdoor storage.

- Moisture Resistance: PP strapping resists moisture, preventing weakening or corrosion.

- Heat Resistance: Steel strapping handles extreme temperatures but may rust over time.

Tip: If your shipments are exposed to the elements, PET strapping is your best bet for durability.

5. Evaluating Joint Efficiency and Sealing Methods

The strength of your strapping isn’t just about the material—it also depends on how it’s sealed. Different sealing methods include:

- Heat Sealing: Melts plastic strapping ends together for a strong bond.

- Friction Sealing: Uses vibration to weld plastic straps, offering quick and efficient sealing.

- Metal Seals: Crimped onto steel strapping, providing the highest joint efficiency.

Choosing the right sealing method prevents weak points in your strapping system.

6. Balancing Cost with Performance

Cost considerations should go beyond the price per roll. Factor in:

- Material Cost: Steel strapping is expensive but extremely strong, while PP and PET strapping offer cost-effective alternatives.

- Equipment Investment: Heat sealers and friction welders require upfront costs but improve efficiency.

- Long-Term Savings: Higher-quality strapping reduces replacements and prevents costly damages.

Investing in the right strapping ensures long-term savings and better product security.

7. Ensuring Compliance with Industry Standards

Using compliant strapping is essential, especially for regulated industries or international shipments. Look for:

- ASTM D3950: Covers plastic strapping used in packaging.

- ASTM D3953: Covers steel strapping requirements.

- ISO 9001 Certification: Ensures high-quality management systems for consistent performance.

Following industry standards improves safety, reduces risks, and ensures regulatory compliance.

Which Is Better: PP or PET Strapping?

When deciding between PP (Polypropylene) and PET (Polyester) strapping, consider your specific packaging needs,

Choose PP Strapping If:

- You need a cost-effective solution for light to medium loads.

- Your goods require minimal resistance to shifting during transit.

- You're packaging lighter boxes or cartons that don’t require high tension.

Choose PET Strapping If:

- You need a stronger and more durable alternative to steel strapping.

- Your shipments involve heavy loads (600+ lbs) and high tension requirements.

- You require UV and environmental resistance for outdoor storage.

Read More : PET Strapping vs PP Strapping - The Best Choice for Your Business

Conclusion: Make an Informed Strapping Choice

Selecting the right industrial strapping is crucial for securing goods, preventing damage, and optimizing packaging efficiency.

By considering material type, tensile strength, elongation, environmental resistance, sealing methods, cost, and compliance, you can make an informed decision that enhances your logistics process.

Looking for high-quality PET strapping for heavy loads? Langgeng Jaya Group offers durable and reliable PET strapping solutions to meet your industrial needs.

Ensure your shipments are safe, secure, and cost-effective with the right strapping choice!