Understanding HDPE Pellets: Properties and Applications

Understanding HDPE Pellets: Properties and Applications

High-density polyethylene (HDPE) is a versatile polymer widely used in various industries due to its strength, durability, and resistance to chemicals.

HDPE pellets, particularly those made from recycled plastic, play a crucial role in reducing plastic waste.

This article briefly discusses the properties and applications of HDPE pellets based on recent research findings.

What Are HDPE Pellets?

HDPE pellets are small granules that can be made from petroleum (virgin) or recycled HDPE plastic waste.

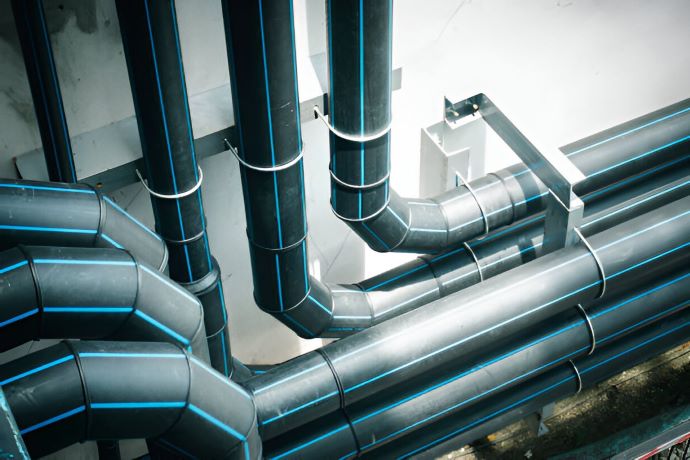

These pellets serve as raw materials for manufacturing various HDPE products, ranging from packaging to construction materials.

HDPE pellets produced from virgin HDPE have different characteristics compared to recycled ones.

Learn More : Recycled HDPE vs. Virgin HDPE - A Comprehensive Comparison

Recycled HDPE pellets, for instance, may contain impurities that affect their thermal and mechanical properties.

Therefore, it is essential to request detailed specifications of recycled HDPE pellets before purchasing.

How Are Recycled HDPE Pellets Made?

The process of producing recycled HDPE pellets is as follows:

- Collecting and sorting plastic waste

- Washing and shredding it into small pieces (flakes)

- Melting and reforming it into pellets

This process not only conserves resources but also helps reduce plastic waste in the environment.

Properties of HDPE Pellets

HDPE pellets, whether virgin or recycled, exhibit different thermochemical characteristics.

According to a study by contributors from the University of Maribor and Brno University of Technology, recycled HDPE degrades at a lower temperature and has a lower degradation rate compared to virgin HDPE.

This difference is due to impurities in recycled materials that affect their thermal stability.

Understanding HDPE pellets' specifications is crucial for their effective application in various industries

Mechanical Properties of HDPE Pellets

The mechanical properties of HDPE pellets are critical for their application in various products.

Research conducted by Bibi Intan Suraya Murat and colleagues found that recycled HDPE exhibits better tensile properties and impact resistance compared to recycled LDPE, although these properties are approximately 10% lower than virgin polymers.

Additionally, adding sawdust filler to HDPE pellets increases their stiffness but reduces impact resistance, demonstrating the trade-offs in material properties when incorporating fillers.

Applications of HDPE Pellets

One innovative application of HDPE pellets is in soil stabilization.

A study by T. Tabassum and T.V. Bheemasetti highlights the use of recycled HDPE and polypropylene (PP) pellets to enhance the strength and ductility of kaolinite-rich soils.

Their experimental findings showed that soil-cement mixtures reinforced with HDPE pellets met the strength requirements for pavement base and subgrade layers, demonstrating the potential of HDPE pellets in construction applications.

For large-scale projects, sourcing HDPE pellets in bulk can be cost-effective and efficient.

Conclusion

HDPE pellets, especially those made from recycled plastic waste, offer significant benefits in terms of material properties and applications.

Continued research and innovation in recycling and applying HDPE pellets are essential for advancing sustainability and reducing plastic waste.

Get an interesting and up-to-date information on plastic recycling only at Langgeng Jaya Group.