Plastic HDPE: The Material Behind Your Everyday Milk Jug

Plastic HDPE: The Material Behind Your Everyday Milk Jug

When you grab a milk jug from your refrigerator, have you ever wondered what makes up this container?

The main material of milk jugs is high-density polyethylene (HDPE). Have you ever heard about HDPE before?

Let’s discuss it further and I will explain why HDPE is the preferred choice for milk jugs.

What Type of Plastic Are Milk Jugs Made Of?

Milk jugs are mainly made of HDPE plastic. This material is chosen because it can provide strength and resistance to impact while it transports.

HDPE is also non-reactive, meaning it doesn't interact with the milk inside. So the product remains fresh and safe for consumption.

Why Is HDPE Used for Milk Bottles?

HDPE is used for milk bottles for several reasons:

- Durability: HDPE's high tensile strength ensures the jugs can withstand drops and impacts during transportation.

- Safety: HDPE is food-grade. So it doesn't leach harmful chemicals into the milk.

- Recyclability: HDPE is highly recyclable. You can start to keep your milk jug and offer it to the recycling company.

- Cost-Effectiveness: HDPE is relatively inexpensive. It helps keep the overall cost of milk production low.

Read More : How Recycled HDPE Is Changing the Packaging Industry

How Thick Is Milk Jug Plastic?

The thickness of milk jug plastic varies. mostly it ranges between 0.5 to 1 millimeter. It’s thick enough to provide the necessary strength and durability while keeping the jug lightweight and easy to handle.

The precise thickness can depend on the manufacturing process and the specific design of the jug.

The Role of HDPE in Milk Jug Production

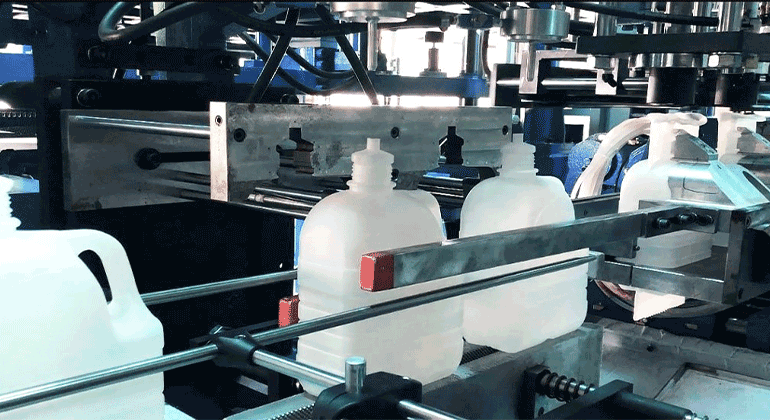

HDPE milk jugs are produced using a process called extrusion blow molding. In this method, HDPE pellets are melted and formed into a tube.

This tube is then clamped into a mold and inflated with air. It will shape into the familiar milk jug form. Excess plastic is trimmed off and recycled back into the process to minimizing waste.

Learn more about the HDPE pellets specification that suits the extrusion blow molding process here.

HDPE Milk Crates: Another Essential Component

In addition to milk jugs, HDPE is also used to manufacture milk crates. These crates are designed to transport multiple milk jugs safely and efficiently. Like the jugs, HDPE milk crates are durable, reusable, and recyclable, contributing to the effectively the dairy supply chain.

Conclusion

HDPE, or high-density polyethylene, is the main material for milk jugs and crates. Because of Its durability, safety, and recyclability make it the ideal choice for the dairy industry.

By exploring the intricacies of milk jug plastic, we can see how HDPE contributes significantly to both consumer safety and environmental sustainability.

Next time you pick up a milk jug, you'll know what it's made of.

Discover More About HDPE Products at Langgeng Jaya Group

Langgeng Jaya Group provides high-quality HDPE pellets or flakes. Whether you're in need of HDPE for Blow or Injection Process, Langgeng Jaya Group has you covered. Learn more about our HDPE products and how they can benefit your business.