Things You Need to Know Before Buying Recycled PET

As public awareness of the negative impact of plastic waste rises, environmentally friendly products are becoming increasingly popular. One of these is daily products made from plastic, such as food or beverage packaging.

Therefore, many plastic packaging manufacturers are seeking and using recycled Polyethylene Terephthalate (PET) materials for their products to be able to label them as “This product is made from environmentally friendly recycled materials.”

PET itself is not only used for packaging products. Various products such as fibers, geotextiles, and mechanical components also use PET as their raw material.

Thus, the demand for environmentally friendly products is likely to expand across various industries.

In this article, we will discuss some important things you need to know before deciding to buy recycled PET (rPET).

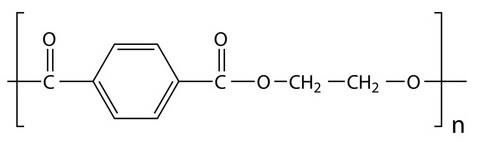

Understanding PET and rPET

Some of you may already be familiar and understand PET well. But there is no harm in refreshing our understanding of PET.

- Properties of PET

PET is known for its high mechanical properties, resistance to chemical and thermal aging, color stability, and wear resistance.

PET can also be processed easily, so this is the main reason why this material is chosen to be made into various products.

- Benefits of rPET

Recycling PET will help address the significant environmental problems that PET waste can cause.

By recycling PET, we convert solid waste into value-added products, reducing plastic pollution and conserving resources.

Applications of Recycled PET

- Construction and Infrastructure

Recycled PET is used in various applications in the construction industry, including geotextiles for erosion control and soil stabilization.

Besides being environmentally friendly, geotextiles made from RPET fibers also have good durability.

- Textile Industry

Recycled PET is also increasingly used in the textile industry due to its flexibility, lightweight nature, and quick-drying properties.

PET fibers, produced through melt spinning or extrusion techniques, are ideal for eco-friendly fabrics.

- Advanced Applications

Innovative uses of rPET include 3D printing filaments, membrane filters for heavy metal removal, and polymer composites to enhance quality and stiffness.

For high-quality recycled PET flakes suitable for various applications, you can consider Langgeng Jaya's RPET clear flakes.

Processing Recycled PET

Understanding the processing methods for recycled PET (rPET) is crucial to ensuring high-quality outcomes. Here are some important considerations:

- Temperature Control

The processing temperature significantly influences the quality of rPET. Optimal temperatures range from 210°C to 270°C, affecting crystallinity and mechanical properties.

Proper temperature control is vital to avoid polymer degradation, which can impact the material's strength and durability.

- Extrusion Process

This involves melting the PET flakes and forming them into new shapes. Proper washing and grinding of PET waste are critical steps to remove contaminants and prepare the material for extrusion.

Effective extrusion ensures the production of high-quality fibers and products suitable for various applications.

- Impact of Processing on Properties

Recycled PET can exhibit similar mechanical properties to virgin PET when processed correctly.

Factors such as crystallinity, tensile strength, and impact resistance are maintained or improved through precise control of processing parameters.

- Additives and Stabilizers

To enhance the properties of rPET, additives and stabilizers are often used during processing.

These materials help improve the thermal stability, color, and overall performance of the recycled polymer.

Careful selection and incorporation of these additives can significantly enhance the quality of the final product.

Quality and Mechanical Properties

Recycled PET (rPET) generally maintains many of the desirable properties of virgin PET, making it a valuable material in various applications. However, the recycling process can affect its quality and mechanical properties in several ways.

- Mechanical Strength

Recycled PET often exhibits slightly lower mechanical strength compared to virgin PET.

This reduction is mainly due to the degradation that occurs during the recycling process, such as chain scission, which leads to shorter polymer chains and, consequently, lower tensile strength and impact resistance.

However, the impact can be mitigated by blending rPET with virgin PET or by using chain extenders during the recycling process, which helps restore some of the lost properties.

- Thermal Properties

The thermal stability of rPET is generally lower than that of virgin PET. This is due to the presence of contaminants and degradation products that form during recycling.

The melting temperature (Tm) and crystallization temperature (Tc) can be slightly reduced in rPET.

Additives or stabilizers can be used to improve the thermal properties of rPET and make it suitable for high-temperature applications.

- Rheological Properties

The viscosity of rPET is typically lower than that of virgin PET, which can affect its processability.

The reduced viscosity is a result of chain scission during mechanical recycling. To improve the rheological properties, chemical modifications such as reactive extrusion with chain extenders can be employed.

This technique helps to rebuild the molecular weight and enhance the flow properties of rPET.

- Durability and Aging

Recycled PET can have similar durability and resistance to environmental stress cracking as virgin PET. However, the presence of impurities and degradation products can affect its long-term performance.

Studies have shown that proper sorting and cleaning during the recycling process can significantly enhance the durability of rPET.

- Applications

Despite some reductions in mechanical properties, rPET is widely used in various applications, including packaging materials, textile fibers, and automotive parts.

Its properties can be tailored through various processing techniques to meet specific application requirements.

For instance, rPET is commonly used in food and beverage containers, where it provides sufficient strength and clarity while promoting sustainability.

Environmental Impact

- Reducing Plastic Waste

Using rPET helps mitigate the negative impact of plastic waste on the environment.

By recycling PET, we reduce the volume of plastic in landfills and lower greenhouse gas emissions associated with producing virgin PET.

- Eco-Friendly Products

Recycled PET products contribute to a circular economy, which will broadly increase economic resilience and reduce reliance on virgin raw materials.

Eco-friendly textiles, packaging, and construction materials made from rPET are crucial for sustainable development.

Challenges and Considerations

- Quality Control

Ensuring the quality of rPET can be challenging due to potential contamination and variability as recycled materials.

It is important to obtain rPET from reputable manufacturers who adhere to strict quality standards. Langgeng Jaya Group has proven capable of providing and maintaining rPET quality in both flake and pellet forms.

- Processing Parameters

Optimal processing parameters, such as temperature and extrusion speed, are crucial for producing high-quality rPET fibers.

Inadequate processing can result in lower mechanical properties and reduced product performance.

Conclusion

Recycled PET offers a sustainable alternative to virgin PET, with various applications in construction, packaging, textiles, and advanced materials.

Understanding the properties, processing methods, and benefits of rPET is essential for making informed purchasing decisions.

By choosing rPET, you contribute to reducing plastic waste and promoting environmental sustainability.

Ensure you obtain high-quality rPET from reputable manufacturers to maximize its benefits and applications.